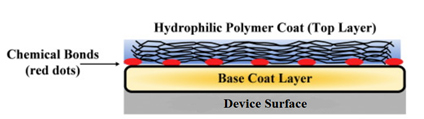

Why hydrophilic coating?

Since polymeric materials are generally inert, low-energy and have a hydrophobic surface, they cause damage to the vein or any canal path in the body with the effect of friction. On the other hand, traumatic complications can occur due to protein adsorption, blood clotting and infection. Therefore, a hydrophilic coating is needed in medical applications.

The main purpose of hydrophilic coating is to provide wettability and to reduce the friction force. Therefore, hydrophilic polymer coating is one of the important applications needed in medical devices such as catheters, stents, vascular and urinary system applications and guidewires.

Slippery, friction-resistant and biocompatible, SENSCOATTM coatings can be applied to devices used in catheters, guidewires, implants and other intra-body applications. These coatings, which help to improve the comfort of the patient at the time of application, also facilitate the process.

As Medichem, we can provide coating solutions from standard products, as well as adapt them to the desired specifications and production processes in line with the customers' request and support our customers in obtaining the most appropriate performance.

Applicable surfaces;

- PVC

- Polyurethane

- Nylon

- Pebax

- Teflon

- Stainless steel

- Silicone

- Polyethylene

Coating properties;

- Transparency

- Excellent lubricity and low friction

- Wear resistance

- Low particle emission

- Biocompatible